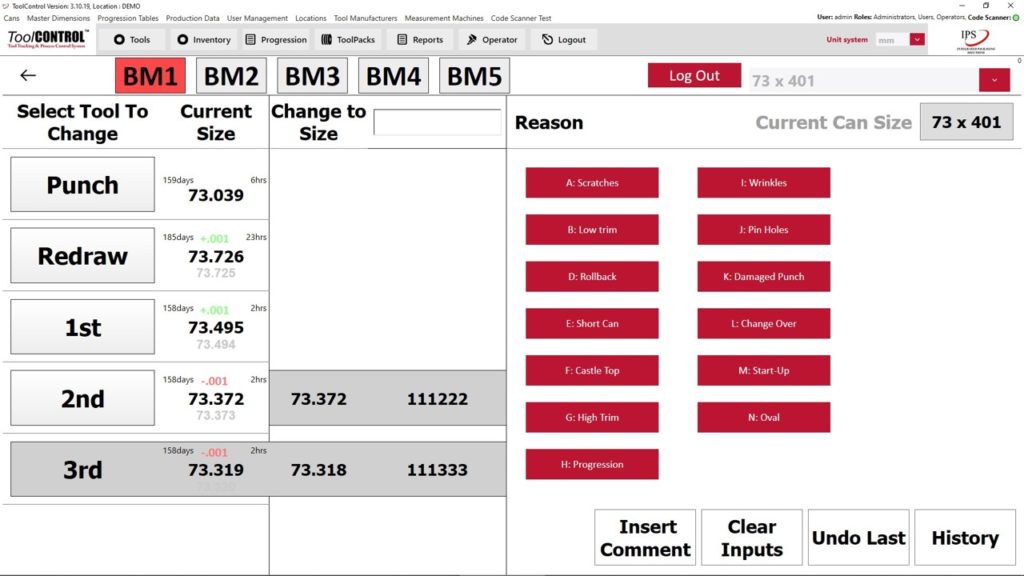

The IPS ToolCONTROL is a tool tracking and inventory control system, designed specifically for the can making industry. The system uses RFID and 2D Barcode scanning technology to make data entry as simple as possible. The ToolCONTROL system is built around three software modules, integrating data from the tool room, bodymaker production data, as well as QA data including can weight and can wall thickness. The ToolCONTROL is the most powerful and easy to use system in the can industry today.

Production Module

- Tool inventory by tool type, size & tool family (i.e. progression)

- Integrated with IPS ToolSCAN 2.0™ measurement gauge

- Tool ID (data matrix code) scans directly into system

Can Weight Module

- Links can weight to specific Bodymaker tooling

- Can weight displayed at Bodymaker interface screen

Necker Inventory Module

- Tracks production data (cans produced) to specific tool

- Tracks tool location to Necker station pocket

Base System + Bodymaker Module

- Tracks production data (cans produced) to specific tool

- Tracks tool location to specific Bodymaker

- Tracks cross hatching and polishing of tools

Enterprise Reporting Module

- Secure cloud-based reporting

- Remote access to key data

- Reporting across multiple locations

Product Videos

Interested in learning more?

Fill out a quick form to connect with our sales team.