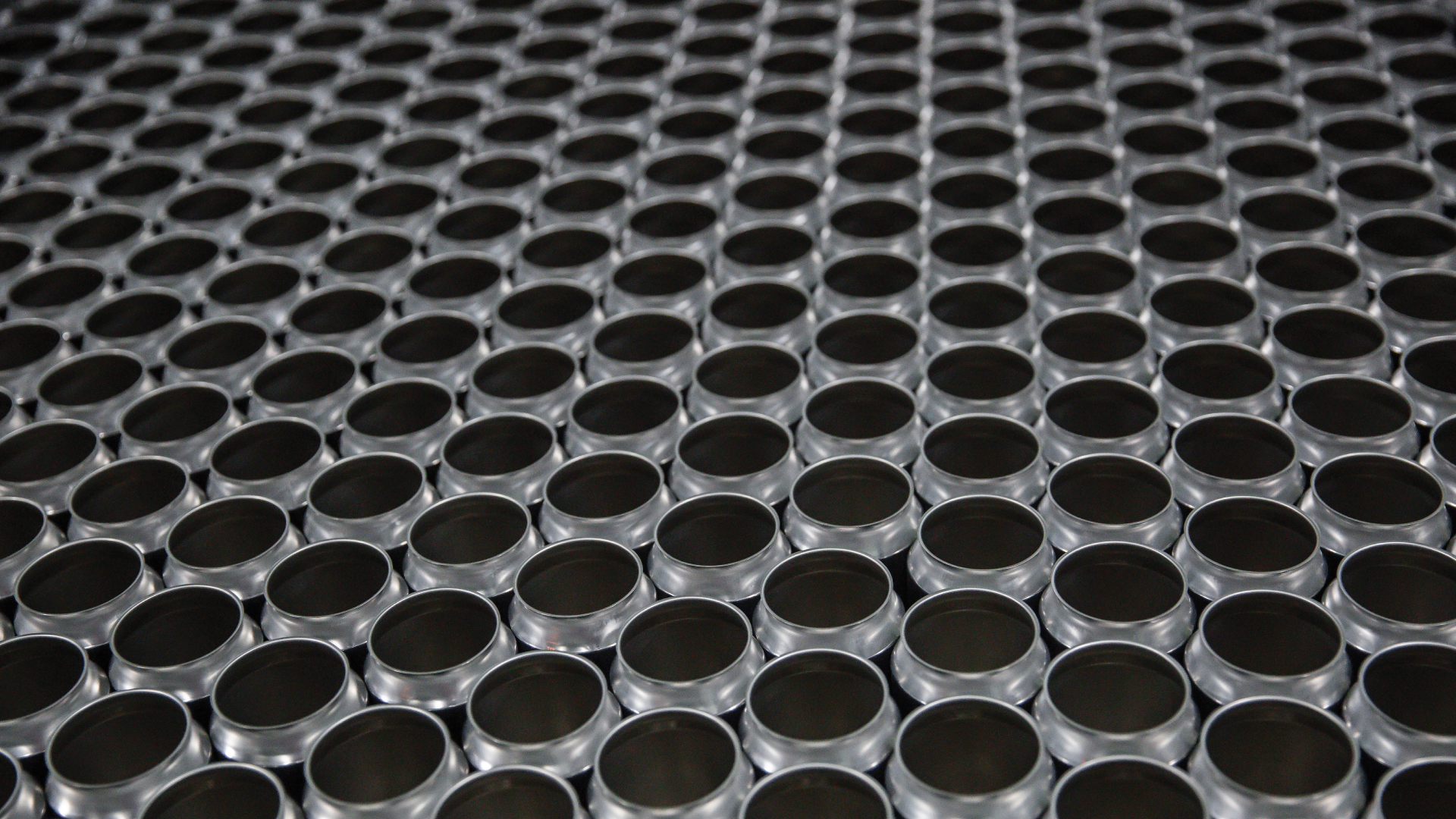

Line Control

Line Control is the brain behind a smooth-running can line. It manages how cans move between machines, regulates accumulation zones, and helps prevent downtime, spoilage, and machine damage. At IPS, we help plants implement and optimize Line Control systems that improve performance, increase uptime, and protect product quality—all while making life easier for operators.