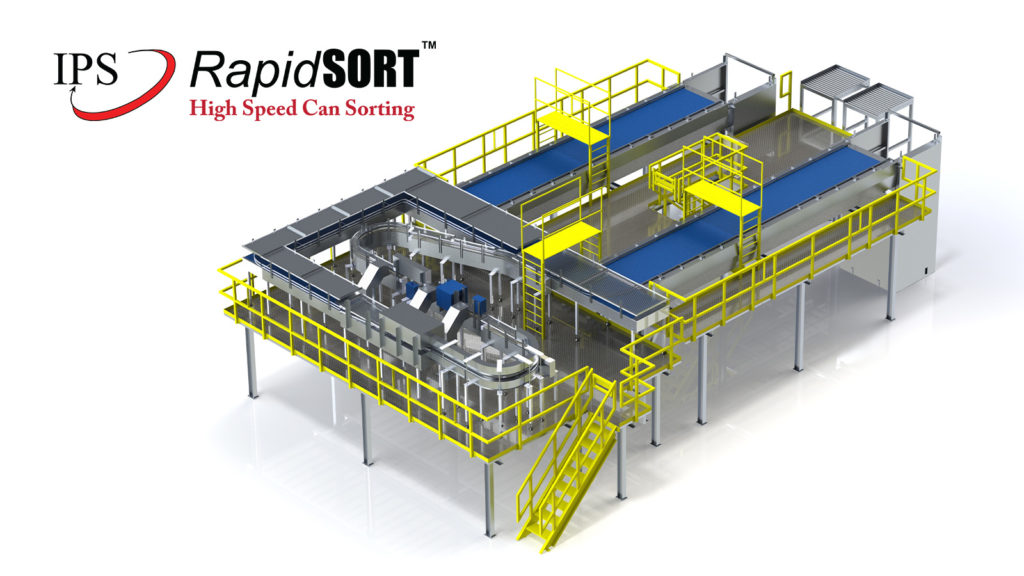

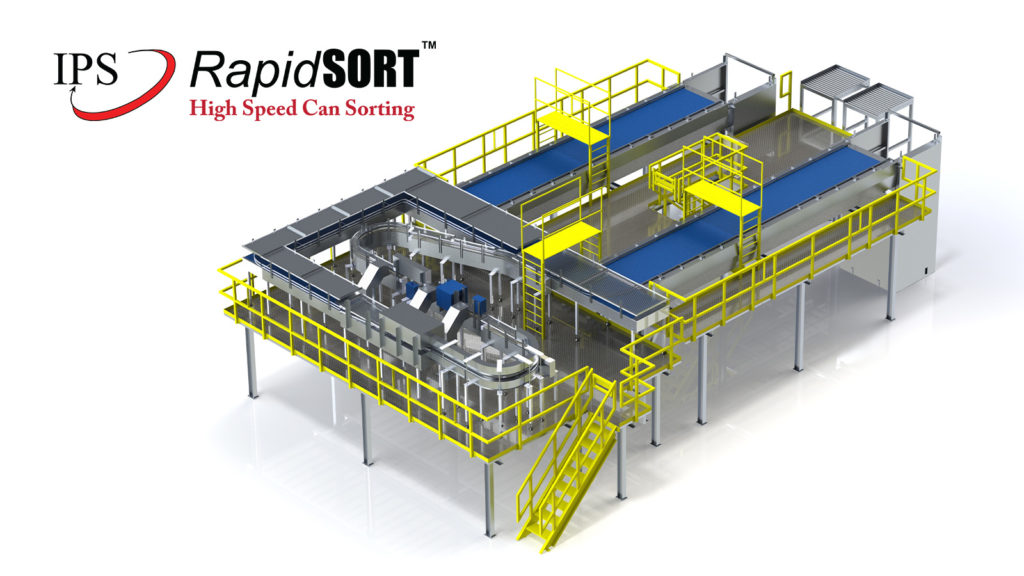

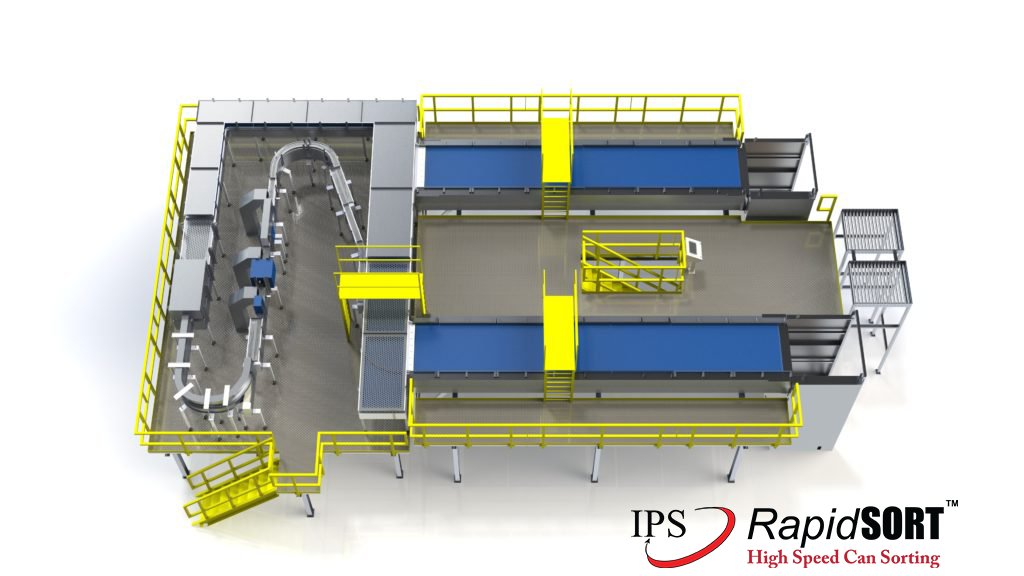

The IPS RapidSORT™ is a high-speed, vision-based HFI (Held for Inspection) can sorting system. The RapidSORT™ is a turn-key system that connects a Depalletizer and a Palletizer with a high speed inspection loop that contains three different camera inspection stations. Capable of quickly inspecting the bottom of the can (for Bodymaker number and ink dot), the inside of the can (for internal defects), and the outside of the can (for decoration defects), the IPS RapidSORT™ ensures accuracy in sorting HFI (Held for Inspection) cans, making sure good cans are sold and bad cans don’t get shipped to customers.

Features

- Identification of Bodymaker ID

- Identification of Ink Dot Color

- Identification of Inside Can Defects

- Identification of Deco Defects

- Automatic Defect Kick-Out

Benefits

- Eliminates manual HFI inspection

- Rapid sorting of HFI pallets

- Sustainability (reducing mass scrap)

- Optional dual-loop for multiple diameters

- Configurable for various Pal/Depals

- Configurable for various Cameras

Product Photos and Videos

Want to learn more?

Fill out a quick form to connect with our sales team.